Products >> Crane >> KPK Light crane system

Light Duty 1t KPK Light Crane Systems with Chain Hoist for Assembly Line

- Product No.:2023622174348

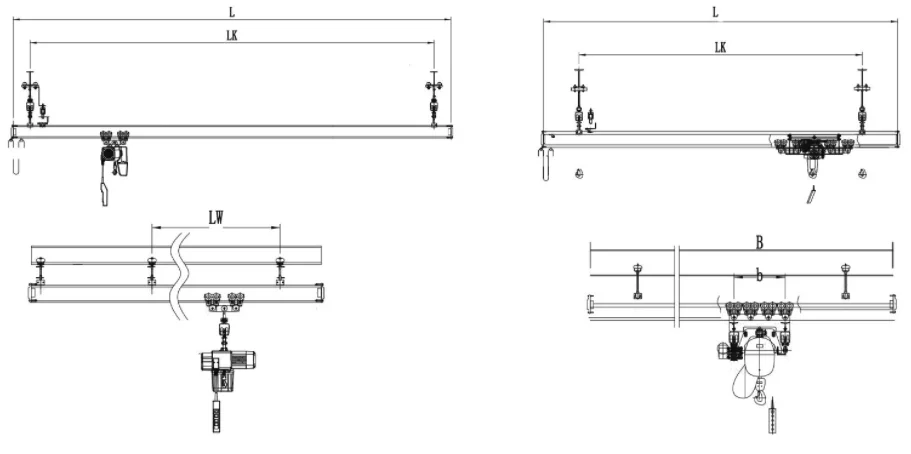

KPK light crane is a general term for flexible beam crane. KPK is composed of suspension device, track, turnout, trolley, electric hoist, mobile power supply device and control device. It can directly transport materials in the air by hanging on the roof or beam frame of the plant. KPK flexible composite suspension crane is characterized by that the main body of steel structure is composed of type rails, and different combinations can form a variety of use forms.

KPK Crane System uses a modular design to replace the traditional concept of a complete machine design.The basic components of the crane function are made to have multiple uses,with the same connection elements and interchangeable standard modules.According to needs,it can be composed of single-girder suspension cranes,double-girder suspension cranes,cantilever cranes,light gantry cranes,and stacker cranes.It can also form large-scale automated material handling systems with safe lifting ranges from 100kg to 5000kg.Lightweight and flexible modular cranes can be operated manually,as well as automatic and semi-automatic operation.The single rail crane can be also made into straight rail , bent rail or other combined rail types .We supply you flexible crane solutions according to different workstation situation .

KPK suspension cranes can be easily moved by hand, which also enables bulky and heavy workpieces to be handled safety and precisely. Since they are suspended from a superstructure, such as roof beams, steel girders or concrete ceilings, they require no additional floor space. Both individual workstations or complete production and storage areas can be fully served with overhead systems.Optimum space utilization and convenient handling are the key features of this system.It is especially suit for modern production Conveyor Line.

KPK system applicable to general workshop,warehouse and working-place where need moving goods low of 3.2t,request environment temperature is -20ºC ~ +60 ºC.The altitude of the KPK system installation location should be no more than 1500m,general work indoors.When the KPK light crane system working in outdoors,in the environment with corrrosive gas and liquid,and teh temperature outside -20ºC ~ +60 ºC,special protective measures should be taken.

Advantages:

- High reliability and stability:KPK light crane system is composed of standard modular parts, which can guarantee mass and high quality production. It can be customized according to customers' individual requirements.

- Strong adaptability:KPK light crane system can flexibly design and install according to the needs of each station in the factory. It can be assembled at will from fixed point to high accuracy multi-point and multi-beat automated transportation lines.

- Safe and reliable handling:KPK single-girder overhead travelling cranes can be easily moved by hand thanks to their low deadweight and smooth-running trolleys. They ensure that heavy and awkward workpieces can also be handled safely and reliably.

- Convenient installation and economic efficiency:KPK light crane system is easy to install and debug. KPK classic single-girder suspension cranes can be simply suspended from the building roof or superstructure. Additional supports for the crane runway are not necessary. Even partial areas of a workshop may be easily fitted with suspension cranes at low cost.

- Strong ability to adapt: KPK system according to the need of plant, the flexibility to design installation crane system, from the point to the highlands, much more beat automated conveyor line, can be arbitrary combination. Can be used in the design of the new plant, also can be used for the renovation and extension of the old system.

- Light weight, convenient handling and easy manual movement.

- Clean, Maintenance-free Operation: No lubrication required.

- KPK rail: cold rolled steel rail, light weight, good rigidity, smooth surface. The light level and intermediate rated lifting weight within the scope of the track, running within design to protect the car and internal sliding contact line (closed).

- Steel support superstructure:Support system can also be used wherever workshop ceilings and roof structures cannot bear loads.High flexibility for planning and configuration,particularly easy assembly

- Suspension components: Hanging in the edge of beams of the plate .The flexible rail hanger, ball and socket, universal joint, threaded connection height is adjustable. Ball joint with soft in the head gasket, eliminating wear and noise.

- Trailing cable:Highly flexible flat cables .Sheath use Special polychloreprene (Butadiene-Acrylonitrile Rubber) which is flame resistance and self-extinguishing and conductor is superfine soft bare copper which purity can reach 99.999%.

- Joint connection: KPK product installation connection, adopt thread connection all the standard parts of each system size (straight rail and rail, rail, wheel, etc.) has the same size, and use the simple plug type bolt connection together.

- KPK trolleys:Excellent smooth-running performance and minimum rolling resistance over their entire service life.Quiet and smooth operation thanks to plastic wheels that are mounted in anti-friction bearings and lubricated for life.Maintenance-free travel wheels with effective shock absorption

- Conductor rail:HFP56 conductor rail is a robust and inexpensive power supply, which is also easy to install and Compact arrangement, corrosion resistance and simple assembly are its essential features.

- Chain hoist:Nante NCH electric chain hoists has been unanimously approved by the crane manufacturer and the end customer based on its excellent quality, good performance, most competitive prices, and it has rapidly become the first choice for customers to purchase light and medium load lifting handling equipment. The product inherits advanced design concepts of Germany, such as compact structure, reliable performance, durability, wide applications of NCH series electric chain hoist.

| Technical Data of KPK System | |||||||||

| Basic Information | Maximum Hanger Spacing of Single Girder LW |

Maximum Hanger Spacing of Double Girder LW |

|||||||

| Model | Load Capacity | Bending Radius | Bending Angle | 250kg | 500kg | 1000kg | 500kg | 1000kg | 2000kg |

| KPK-0 | 125kg | ≥1000mm | 10°~90° | / | / | / | / | / | / |

| KPK-I | 500kg | ≥1000mm | 10°~90° | 2.8m | / | / | / | / | / |

| KPK-II | 1000kg | ≥1500mm | 10°~90° | 6.0m | 3.8m | 1.8m | / | / | / |

| KPK-III | 2000kg | ≥1500mm | 10°~90 | 6.8m | 6.0m | 3.5m | 7.5m | 6m | 3.5m |

Products Category

Contact Us

Tel: +86-18868812741

E-mail: sylvia.zhao@bravomac.com

Skype: osylvia925

WeChat: missnut925

Whatsapp: +8618868812741

Add: 64-1-201, No5 Hongkun ldeal City, Baijuyi Road, Development Zone, Langfang City, Hebei Province

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry